What is the PREMA project?

PREMA Goals

The PREMA project is an enabler of Predictive Maintenance (PDM) within the Industry 4.0 paradigm, using IoT and Data Analysis to extract information and acquire knowledge about the real-time behavior of objects subjected to vibrational stress or machinery that has parts somehow strongly exposed to vibration.

The aim of the project is to minimize damage to the machines, through predictive analysis that allow intelligent and targeted maintenance interventions, with the final goal of avoiding critical breakdown situations or emergency of the analyzed system, through a combination of:

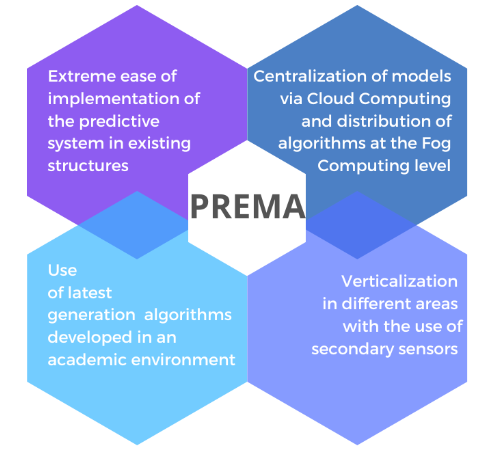

PREMA has several innovative elements compared to the maintenance state-of-the-art platforms, such as:

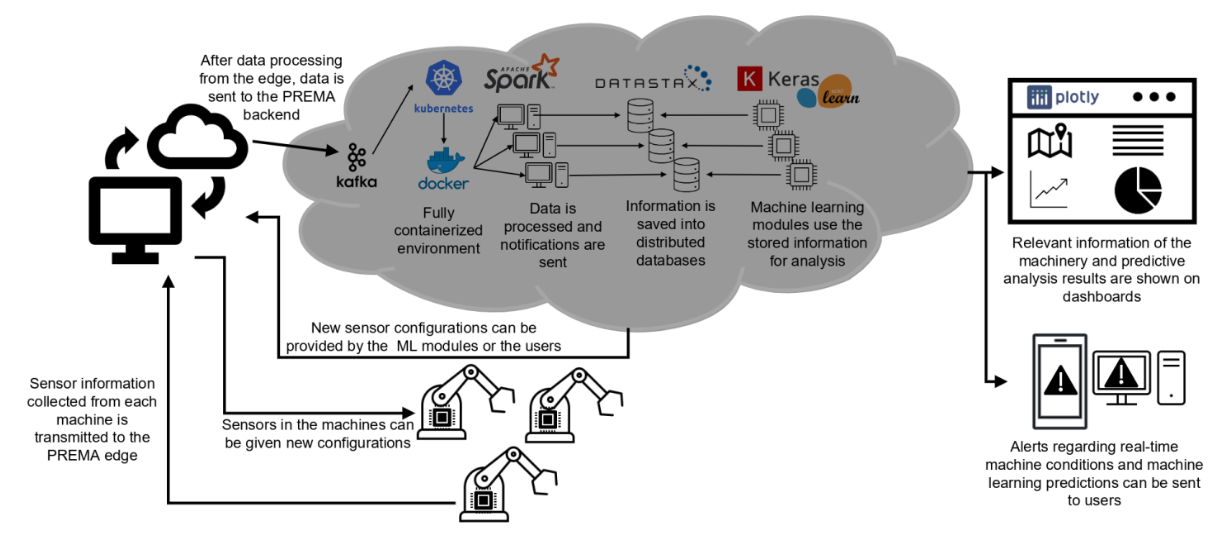

PREMA architecture

The first tests have been performed for glass manufacturing machines of Bottero.

We then transitioned to a complete and finalized platform, having as pilot the design and construction of vibratory feeding and orientation systems for industrial automation, i.e. Brovind industrial vibrators machines.

The platform is composed of Sensors, Edge Devices, Databases, powerful ML Models, Frontends (dashboards and Mobile App):

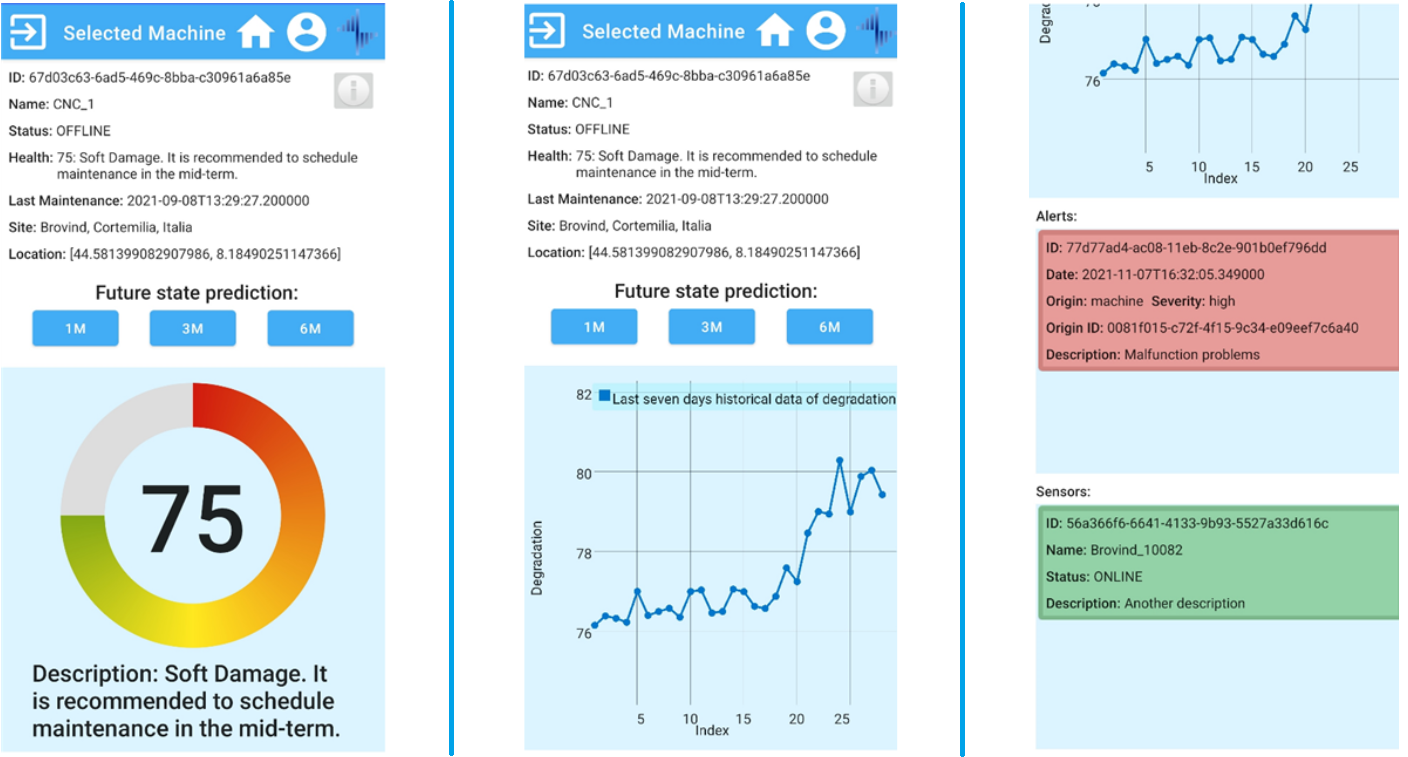

PREMA dashboards

PREMA provides a personalized Android App and custom Dashboards, to favor the immediate access to the factory information and to allow interaction with the components on the Cloud.

Both the dashboard and the application allow the user to check the status of the different machines in the factory, in turn, it shows the readings made by the sensors and the alerts generated automatically by our system when values are recorded that indicate issues in the machinery.

For engineers and data scientists, our frontend provides multiple alternatives to monitor, edit and add custom cloud-based Machine Learning Models. Plus, it allows to check their performance over time to spot under-fitting to the factory conditions.

The design of the PREMA platform enables the boost, evolution and adaptation of Machine Learning Models to seasonal needs, changes in machinery or work sequences that occur throughout the company’s journey.

Additionally, the frontend elements are designed to host multiple types of accounts, providing custom layouts for the various roles within the maintenance and production teams.

PREMA added value

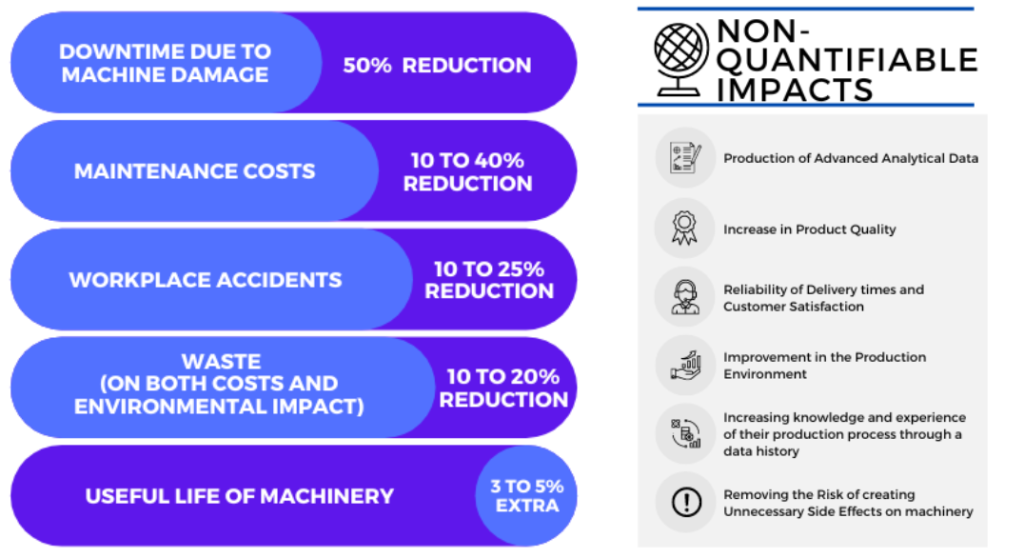

PREMA leads to several improvements compared to traditional maintenance systems:

PREMA also brings several major advantages over current maintenance systems for machinery subject to vibrational stress and which the end customer take advantage of, as:

The project has been assessed as “disruptive” by leading European companies, taking advantage of an opportune historical period for the development of IoT, of three complementary Piedmonts partners and two highly specialized European research organizations (based in Italy and Portugal) and including a long list of “intelligent” technological innovations.

In collaboration with: